smart-sized modular

pick-and-place

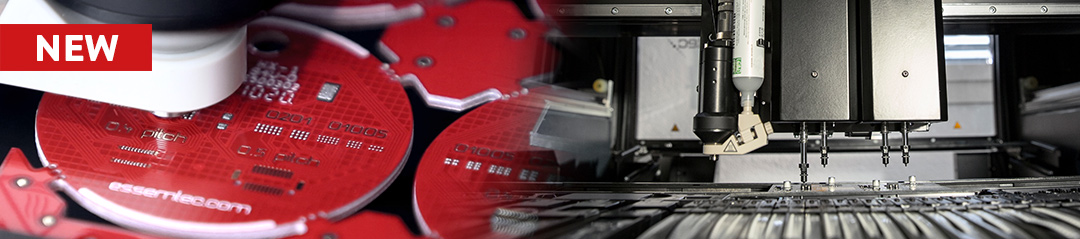

Introducing - The Fox technology - for all types of components and devices. Expandable in any direction. The Fox can drive up to 200 feeder, illustrating its dedication to high-mix production. Due to its small footprint and reasonable weight, the machine is ideal for use in limited space production areas even those located on upper floors.

| Fox4 | Fox2 | Fox | ||

|---|---|---|---|---|

| Productivity | Optimum placement speed | 18’800 cph (4-axes) | 12’000 cph (2-axes) | 7’000 cph (1-axis) |

| Optimum - New Fox Ultra | 31’000 cph (4-axes) | 18’000 cph (2-axes) | 9’500 cph (1-axis) | |

| Solder Paste Jetting Shockwave Jet Valve Jet-on-the-Fly | - | Max Frequency: 780’000 dots/h BGA Pattern Speed: 480’000 dots/h Average board speed: 280’000 dots/h | ||

| Feeder | Feeder Capacity 8 mm Tape | 200 (140 inline) | 180 (120 inline) | 180 (120 inline) |

| Components | Component Size Range | 008004 (imp.) - 109 x 87 mm | (Note specs for details) | |

| Accuracy | Placement accuracy (x, y) | Chip ± 40 μm (3σ) / QFP ± 30 μm (3σ) | ||

| PCB | Max. PCB dimensions | 406 x 305 mm (16 x 12“) | ||

| Dimensions | Machine footprint | 880 x 1090 mm (34.7 x 43“) |

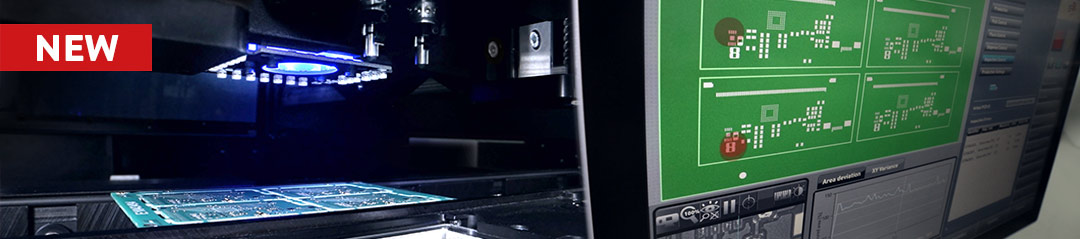

Multitalent Software

at your Fingertips

State of the art, full graphics, 21.5”, 16:9 HD wide touch screen, fingertip operation, universal CAD conversion,

zoom at camera windows, all-in-one job planning, setup optimisation, stock management, ERP/MES connection,

data analysis, line management and more.

Review from BRAUN GmbH

It was necessary to develop a new production strategy. The aim was to minimize downtimes in the entire production chain, taking into account a minimum number of employees in production. The aim was to master the complex production requirements with minimal effort on the line and thus reduce production costs.

Review from E-REON BV

Many of their clients are world-renowned companies who rely on E-REON to help them further innovation in this market segment. The company just invested, for the first time, in a rapid prototype centre incorporating Essemtec Fox MFC equipment.

| Piezo Jet | Shockwave Jet | Volume | Screw | Time-Pressure | ||

|---|---|---|---|---|---|---|

| SMD-Adhesives, Underfill, Silver Epoxy, UV-Adhesives, Globe Top, Encapsulation, Dielectric Ink | Solder Paste, Liquid Metal | Underfill, Gasketing, Globe Top, Dam and Fill, Solder Paste | Solder Paste, SMD-Adhesive, Globe Top, Encapsulation, Silver Epoxy, Dam and Fill | Gasketing, Globe Top, Encapsulation, Solder Paste, SMD-Adhesive, Silver Epoxy, Dam and Fill | ||

| Low - High Viscosity | High Viscosity | Low - High Viscosity | High Viscosity | High Viscosity | ||

| Max Frequency: 2’000’000 dots/h BGA Jet-on-the-Fly: 780’000 dots/h BGA Stop & Jet: 177’000 dots/h | Max Frequency: 780’000 dots/h BGA Jet-on-the-Fly: 480’000 dots/h Average Speed: 280’000 dots/h | 26’000 dots/h (BGA Pattern*) | 30’000 dots/h (BGA Pattern*) | 38’000 dots/h (BGA Pattern*) |

* Full Speed, Dot size 0.5 mm, dot matrix 0.8 x 0.8 mm, 1000 dots, medium: Loctite 3621

Optional Equipment

For our Pick-and-Place

Since 1991, we have been evaluating and developing solutions for your electronics production in cooperation with you.

Due to their highly flexible design, the modular machine platforms are ideally suited for RFNS (Request For Non-Standard).

Our engineers assist you in the development of your production process, on request.

Learn more...

![]()

Naturally adaptive

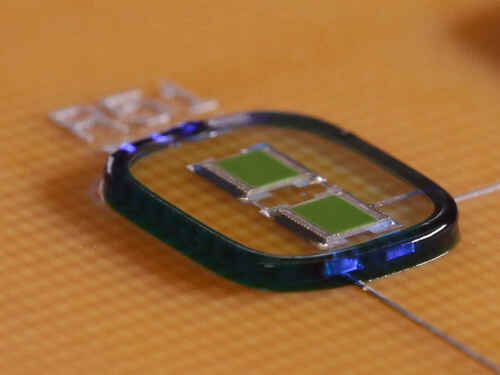

Configurable heads with 1-4 placement-axis. 2,5D and 3D dispensing and jetting, High resolution digital vision system with auto component teach-in and irregular ball recognition. Full operator support - Automated error analysis & KPI. Training, support and troubleshooting via advanced remote access. Investment protection; all options and heads retrofittable. Multi flexible feeder, multi lane cassette or highly accurate single lane feeder. Tape, Stick, Strip, Tray slider. Largest component spectrum; 008004 up to 109 x 87 mm, height up to 25 mm.