RELENTLESS ALL-TERRAIN DISPENSER

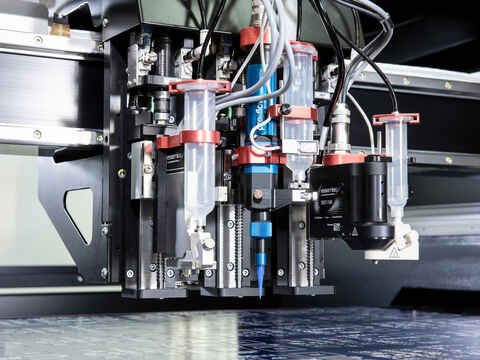

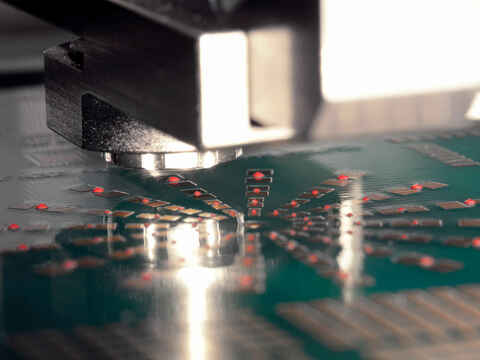

Introducing - The Tarantula - State of the art technology, easily integrated in any line. Wide range of dispensing applications such as Solder Paste and SMT Glue, LED Encapsulation, Silver Epoxy, Dam and Fill, Underfill, Cavity Fill, 3D Dispensing via laser height mapping and more.

| Tarantula | ||

|---|---|---|

| Process | Jetting / dispensing speed | Piezo Jet Valve Max Frequency: 2’000’000 dots/h BGA Pattern Jet-on-the-Fly: 780’000 dots/h (glue) BGA Pattern Stop & Jet: 177’000 dots/h |

| Shockwave Jet Valve for Solder Paste Jetting Max Frequency: 780’000 dots/h BGA Pattern Jet-on-the-Fly: 480’000 dots/h Average board speed Jet-on-the-Fly: 280’000 dots/h | ||

| Time Pressure Valve BGA Pattern speed: 38’000 dots/h | ||

| Archimedean Screw Valve BGA Pattern speed: 30’000 dots/h | ||

| Volume Valve BGA Pattern speed: 26’000 dots/h | ||

| Dispensing mode | Dot, line, curve, interpolated 3D contour | |

| Accuracy | Placement XY dots | ±40 μm (3σ) |

| Positioning Z axis | ±20 μm (3σ) | |

| PCB | PCB dimensions | 560 x 610 mm (22 x 24“) |

| Dimensions | Machine footprint | 1’557 x 1’357 mm (61 x 53“) |

Multitalent Software

at your Fingertips

State of the art, full graphics, 21.5”, 16:9 HD wide touch screen, fingertip operation, universal CAD conversion,

zoom at camera windows, all-in-one job planning, setup optimisation, stock management, ERP/MES connection,

data analysis, line management and more.

![[Translate to Englisch:] Essmetec AG and Hekatron Tarantula Dispensing](/fileadmin/user_upload/news/2018/06_Juni/Connected-town-Hekatron-Essemtec-AG.jpg)

Review Rohde & Schwarz

For over 30 years, efficiency, technology and quality have been continuously promoted, especially in SMT production. However, new technical developments of modern assemblies led to new requirements for a combined gluing and soldering process in the SMD assembly. The aim is to reduce manufacturing costs through improved automation and ensure the high quality standards.

Review from Hekatron GmbH

Industry 4.0 increasingly encourages the remote observation and inspection of systems. Hekatron assembles its products exclusively in Germany. They currently use Essemtec “Spider” & "Tarantula" dispensers to conduct the dispensing applications for their SMD large-scale production in Sulzburg.

| Piezo Jet | Shockwave Jet | Volume | Screw | Time-Pressure | ||

|---|---|---|---|---|---|---|

| SMD-Adhesives, Underfill, Silver Epoxy, UV-Adhesives, Globe Top, Encapsulation, Dielectric Ink | Solder Paste, Liquid Metal | Underfill, Gasketing, Globe Top, Dam and Fill, Solder Paste | Solder Paste, SMD-Adhesive, Globe Top, Encapsulation, Silver Epoxy, Dam and Fill | Gasketing, Globe Top, Encapsulation, Solder Paste, SMD-Adhesive, Silver Epoxy, Dam and Fill | ||

| Low - High Viscosity | High Viscosity | Low - High Viscosity | High Viscosity | High Viscosity | ||

| Max Frequency: 2’000’000 dots/h BGA Jet-on-the-Fly: 780’000 dots/h BGA Stop & Jet: 177’000 dots/h | Max Frequency: 780’000 dots/h BGA Jet-on-the-Fly: 480’000 dots/h Average Speed: 280’000 dots/h | 26’000 dots/h (BGA Pattern*) | 30’000 dots/h (BGA Pattern*) | 38’000 dots/h (BGA Pattern*) |

* Full Speed, Dot size 0.5 mm, dot matrix 0.8 x 0.8 mm, 1000 dots, medium: Loctite 3621

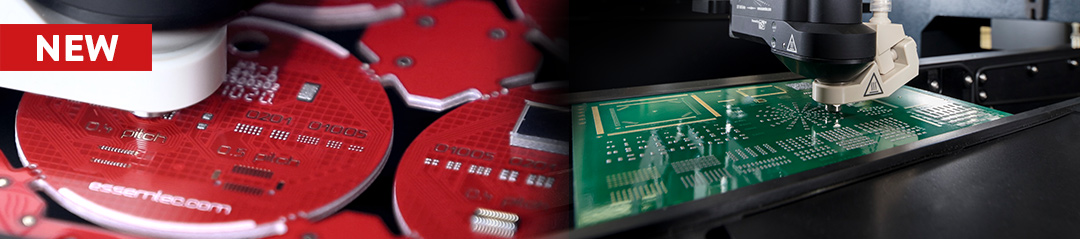

Optional Equipment

For our Dispensers

Since 1991, we have been evaluating and developing solutions for your electronics production in cooperation with you.

Due to their highly flexible design, the modular machine platforms are ideally suited for RFNS (Request For Non-Standard).

Our engineers assist you in the development of your production process, on request.

Learn more...

Naturally adaptive

Integrate into high speed lines and highly complex dispense applications. Three processes at the same time. Plug and Play for valve change. Piezo Jet Valve - super high speed for low viscosity. Solder Jet, Volume Displacement, Time/Pressure, Archimedean Screw Valve. Full operator support - Automated error analysis & KPI. Training, support and troubleshooting via advanced remote access. Investment protection; all options and heads retrofittable.