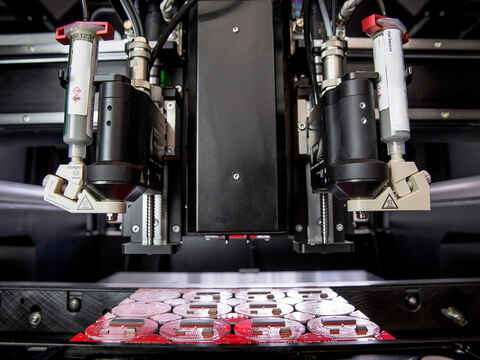

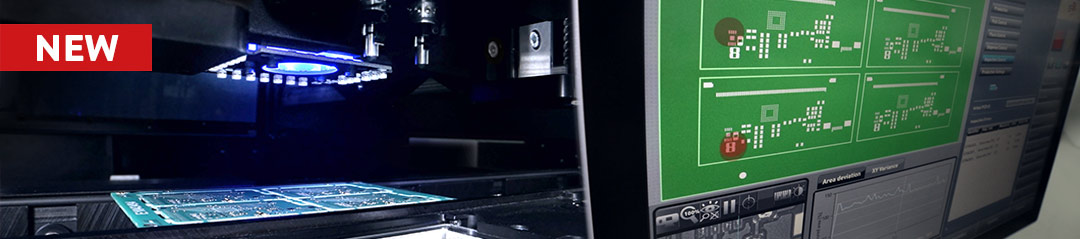

Solder Paste Jet Printing, Glue Jetting and Pick & Place on a single platform

Precise and fast! Introducing the flexibility and scalability of PCB production on a minimal floorspace. By combining several processes on a single machine, hundreds of feeder options and a choice of valve options, you can quickly produce and test new electronic designs. Fastest time to market accelerates profitability in the industry through agile job changeover powered by our intuitive ePlace software.

| Solder Paste Jetting: Shockwave Jet Valve | |

|---|---|

| Viscosity range | < 2’000’000 mPa*s |

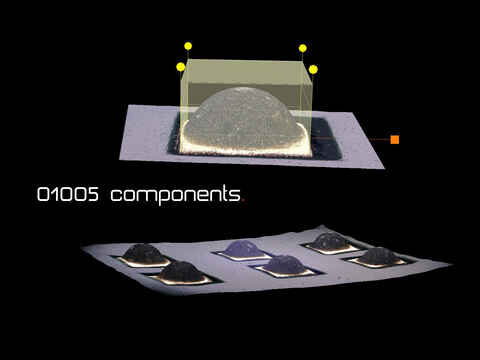

| Min. possible dot diameter/ volume | > 200 μm / > 1.9 nl |

| Jetting speed Jet-on-the-Fly | Max Frequency: 780’000 dots/h BGA Pattern Speed: 480’000 dots/h Average board speed: 280’000 dots/h |

| Useable applications | Solder Paste in electronics, Jetting in cavities and different Z-level, Jetting on populated boards |

| Useable solder pastes | Type 4-7 (jettable), recommended pastes: Indium, WinDot, ... |

| Valve heater | Included, max. 60°C |

| Useable cartridge sizes | 5 ccm / 10 ccm / 30 ccm |

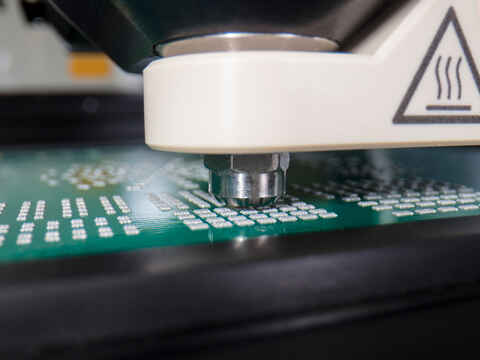

Integrated Inspection System - I2S

![[Translate to Englisch:] Puma Combined Pick and Place and solder Paste Jet Printer](/fileadmin/user_upload/produkt/dispensing/Solder_Paste/Bild/Essemtec-Puma-Combined-pick-and-place-jet-dispensing.jpg)

FROM NPI TO MID RANGE,

UP TO INTEGRATION IN HIGH SPEED LINES

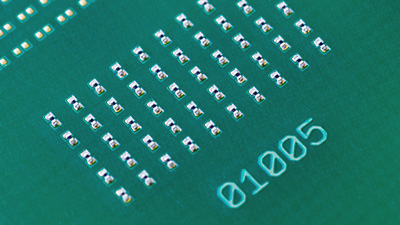

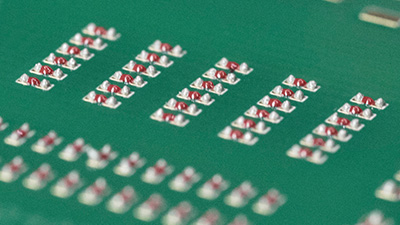

This Non-contact jet printing valve has been developed to jet solder pastes from class 4 to 7, jettable types only.

Integrated and combined with a Pick-and-Place process in one of Essemtec's platforms it opens the possibility of an

"All-In-One" production, enabling customers full flexibility to process complete PCB's within only one machine.

Review from Lumitech

LUMITECH Manufacturing Services GmbH builds LED modules based on surface mount devices (SMD) and chip on board technology (COB). Solder jet printing and other dispensing applications were jointly tested in this high-tech environment. Due to the strategic decision within LUMITECH, the lead time in prototype construction as well as in small production batches could be reduced considerably.

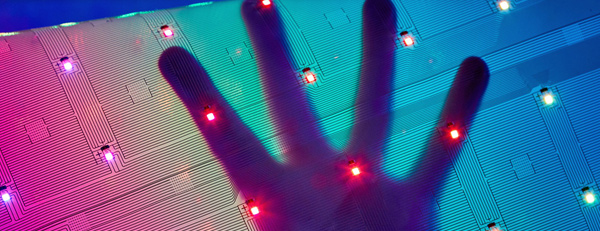

Review from LIGHTNTEC

In Karlsruhe, the innovative high-tech material ledTec.flex, which as a high-performance film monitor can be used indoors and outdoors without any problems, is produced with the support of Essemtec. The pixel-controlled LED film is wafer-thin, ultra-light, flexible, cut to size and bright.

Time to market -

No Printer, No Stencils

Freely selectable and combinable settings of jet parameters for optimal adaptation to customer requirements and characteristics of the dispensing material.

The dynamic shockwave technology allows to jet several hundred shots within just a second and with high accuracy and repeatability.

Contact our Sales or Service Team for more information