New Potential for

your Pick and Place Setup

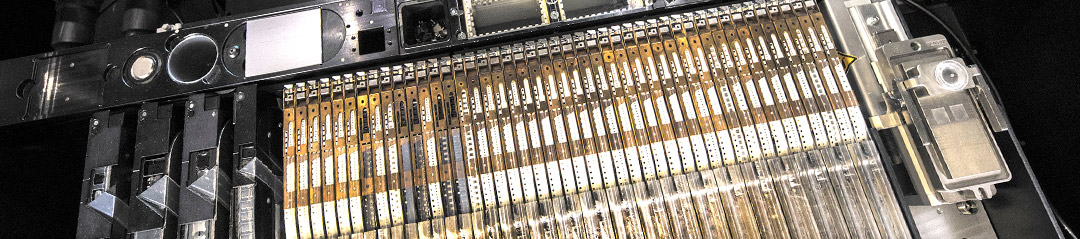

Introducing - the operator time saver - for all types of devices. Full traceability down to single component. Highest throughput is not achieved by high placement rates only, but by intelligent feeder concepts for the fastest possible set up and change over with zero downtime on your SMT machines. Even complex boards can be assembled on a single machine allowing fast changeovers and higher throughputs.

Modular

space saving - intelligent

all shapes, any size

Up to 200 feeder lanes on 1 m² / 280 on 2 m², Best in its class feedercount per square meter,

008004 up to 109 x 87 mm, height up to 25 mm, Hot swap, production optimization algorithms,

Quadro loop 01005 component picking, Traceability and advanced material management

|

single lane and dual lane tape

Evo & hyQ - fastest on-the-fly feeder changeover. 01005 - highest index speed and accuracy in this machine class. Intuitive handling.

clm multi lane cassette

Desinged for easy and fast setup. Economical, intelligent operation of up to 10 lanes tape per cassette. 0201 components - 72 mm tape width.

stick, tape strip, cut-off

Tape cut-offs are common in prototyping and NPI production. Those feeder accommodate all types of tapes and widths and can be kitted directly on the machine.

fixed trays, tray changer, tray slider

Unique tray setup solutions. Tray Changer for up to 18 JEDEC trays. Tray Slider without loosing feeder space or board size. Freely programmable positions.

customized solutions

Integration & development of customized feeding solutions, such as Barcode Label, Vibratory Bowl, Dipping Station, THT, LED’s and extra tall devices.

compatibility

Multi flexible component feeding concept - Chaotic feeder placement. Speed optimization algorythms. Status LED for easy changeover concept definition.

changeover times

Modular concept to gain optimum performance in availability of components without setup changes. Optimize product changeover time down to zero.

highest flexibility

Quadro loop of components. Standard nozzles for all common SMT components, but also for LED’s, bare dies, switches and a multitude of specialities.

operator support

Full operator support - barcode set up, automatic recognition via camera system. Component teach-in via self learning software & more.