Precise, Flexible

High Speed Dispensing

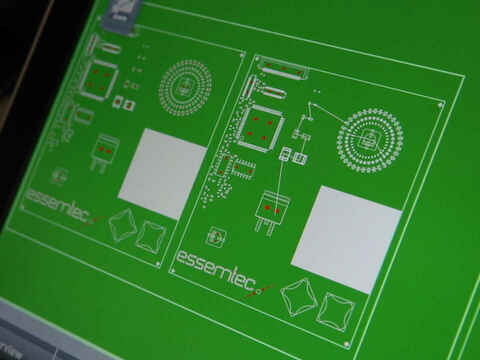

Introducing - our valve technologies - wide range of dispensing applications such as Solder Paste and SMT Glue, LED Encapsulation, Silver Epoxy, Dam and Fill, Underfill, Cavity Fill, 3D Dispensing via laser height mapping and more.

| Piezo Jet | Shockwave Jet | Volume | Screw | Time-Pressure | ||

|---|---|---|---|---|---|---|

| SMD-Adhesives, Underfill, Silver Epoxy, UV-Adhesives, Globe Top, Encapsulation, Dielectric Ink | Solder Paste, Liquid Metal | Underfill, Gasketing, Globe Top, Dam and Fill, Solder Paste | Solder Paste, SMD-Adhesive, Globe Top, Encapsulation, Silver Epoxy, Dam and Fill | Gasketing, Globe Top, Encapsulation, Solder Paste, SMD-Adhesive, Silver Epoxy, Dam and Fill | ||

| Low - High Viscosity | High Viscosity | Low - High Viscosity | High Viscosity | High Viscosity | ||

| Max Frequency: 2’000’000 dots/h BGA Jet-on-the-Fly: 780’000 dots/h BGA Stop & Jet: 177’000 dots/h | Max Frequency: 780’000 dots/h BGA Jet-on-the-Fly: 480’000 dots/h Average Speed: 280’000 dots/h | 26’000 dots/h (BGA Pattern*) | 30’000 dots/h (BGA Pattern*) | 38’000 dots/h (BGA Pattern*) |

* Full Speed, Dot size 0.5 mm, dot matrix 0.8 x 0.8 mm, 1000 dots, medium: Loctite 3621

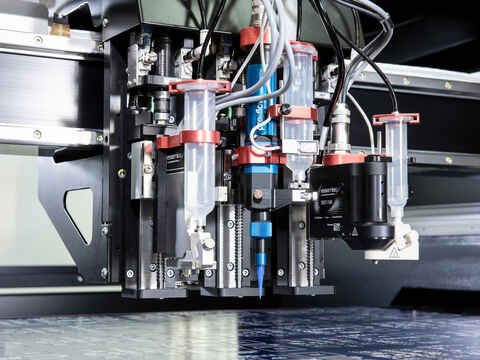

Dispensing Valves

for all Applications

With up to three valves per machine, our dispensers open up a variety of possibilities.

Different dispensing technologies can thus be applied in one go, without further changeovers.

A user-friendly, flexible software controls all processes and displays them in real time.

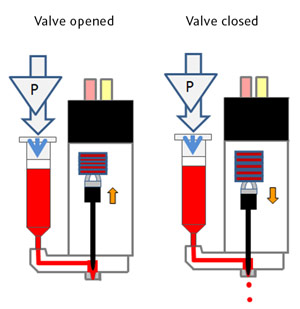

Solder Paste Jet

PIEZO JET

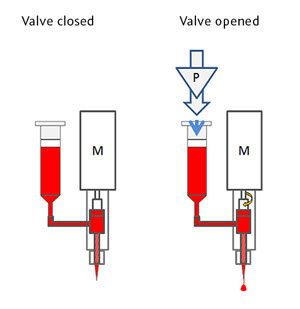

Volume

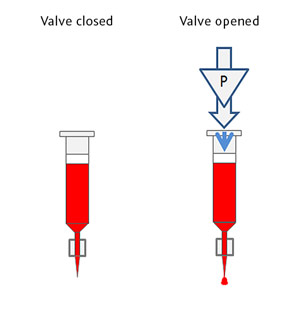

Time-Pressure

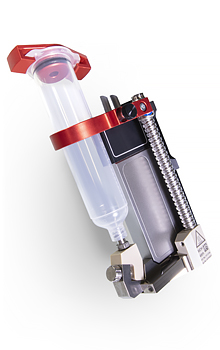

Screw

| Description |

|---|

| High speed non-contact jetting |

| Dynamic shockwave jet technology |

| Free selectable and combinable settings |

| Integrated valve heating |

| Usable / Recommended applications |

|---|

| Solder paste jet printing, jetting in cavities |

| Description |

|---|

| High speed non-contact jetting |

| piezoelectric jet technology |

| Free selectable and combinable settings |

| Usable / Recommended applications |

|---|

| SMD-/UV-/AG-Adhesives, Underfil, Dam&Fill, |

| Encapsulation, LED, Grease, Oil, etc. |

| Optional |

|---|

| Level Control, Valve Heater |

| Description |

|---|

| Endless piston dosing principle |

| Self-sealing rotor/stator design |

| Special screw geometry allows endless dosing flow |

| Usable / Recommended applications |

|---|

| Sealing, Gasketing, Dam&Fill, Underfill, |

| Globe Top, Thermal Grease, etc. |

| Optional |

|---|

| Level Control, Needle Heater, Micron-S needle kit |

| Description |

|---|

| Controlled pressure pulse |

| Very robust, reliable valve |

| No maintenance, easy to clean |

| Usable / Recommended applications |

|---|

| SMD-/UV-Adhesives, AG-Adhesives, Dam&Fill, |

| Encapsulation, etc. |

| Optional |

|---|

| Level Control, Needle Heater, Micron-S needle kit |

| Description |

|---|

| High precision stainless steel screw |

| Encoder controlled motor |

| Screws: shallow, standard, deep, ultra deep |

| Usable / Recommended applications |

|---|

| Solder Paste, SMD-Adhesives, Silver-Epoxy, etc. |

| Optional |

|---|

| Level Control, Needle Heater, Micron-S needle kit |

Naturally adaptive

Conductive and non-conductive joining processes are seeing rapid growth in electronic manufacturing thanks to improvements in the formulation of fluids, pumps and modern dispensing equipment. These technologies open up a wealth of applications such as MEMS packaging, exact LED positioning, heavy component placement or power modules to name just a few. Our machines are easily integrated into high speed lines and highly complex dispense applications. Three processes at the same time. Plug and Play for valve change. Piezo Jet Valve - super high speed for low viscosity. Solder Jet, Volume Displacement, Time/Pressure, Archimedean Screw Valve.