Visit Essemtec and Nano Dimension in Hall B2.103 and Hall A3.134. Be inspired by our innovations in Solder Paste Jetting with 3 times higher speed, Integrated Inspection System, Intelligent Material Management, component placement, re-balling and repair processes, and much more.

High-Speed Solder Paste Jetting - for all product platforms

Since 2019 Essemtec continuously improved the solder jetting process. More than 100 systems are worldwide in production. At Productronica a huge, improved solder jet speed of 180’000 – 400’000 dots/h will be presented. It is now possible to exchange inflexible solder screen printer with a P&P integrated solder jetting solution to serve up to 3 Pick and Place machines. SMEs solder jet products in All-in-One Systems or high-speed production integrate the system for process improvement capability.

See all these breathtaking benefits live in the Essemtec booth.

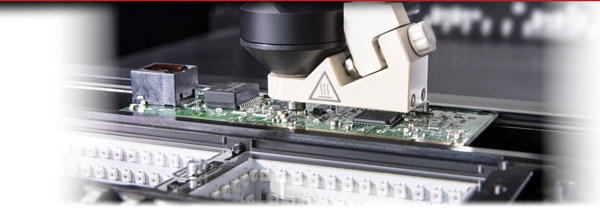

Integrated Inspection System - for all product platforms

First time in the industry an Integrated Inspection System (I2S) in the Pick and Place and dispensing solutions is presented at Productronica. The Integrated Inspection System is available for inspection of dispensed and jetted material as well as placed SMD components right after the process, to ensure only good, inspected products are entering the reflow ovens. The process also includes an automated repair function. The system is already integrated in automotive and complex production sites but also at KMUs which partially can avoid investing in expensive SPI and AOI systems.

Smart Material Management - integrated solution for factory 4.0

The affordable material management solution is a fully integrated end-to-end solution for electronics manufacturing factories and covers all different storage location. The solutions enable the right material to reach the right place at the right time. The traceability is precise down to individual component. The solution is expandable and flexibly controlled by an intuitive eStorage software, from simple barcode-labelled storage location to fully automated storage cabinets and pick by LED. The solution offers high ROI and is fully integrated with the production machine and the ERP systems.

Our solutions address different areas of electronics production:

- ALL-IN-ONE NPI

- HIGH-MIX LOW-VOLUME

- HIGH-SPEED DISPENSING

- PRINTED ELECTRONICS

- COMPLEX VOLUME REPAIR

- SOLUTIONS BEYOND SMT

What it's all about in detail and in which solutions you discover your benefit, you will find out in the next lines. All these solutions and much more can be seen live at the Essemtec booth.

ALL-IN-ONE NPI

All-in-One multifunctional solution with dispensing & pick and place combined in one machine. Very high feeder count together with an ultra-flexible machine and user-interface represent the perfect solution for small and medium sized batches, prototyping and transfer to serial production. The solution can be expanded at any time based on demand.

HIGH-MIX LOW-VOLUME

With ever-shrinking batch sizes and increasing product changes, the efficiency and productivity of an SMT assembly line are determined by the speed of changeovers. The solution combines multiple machines in a line with extended feeder space, storage capability, and software to enable a fast changeover. With various options, the solution can be tailored to customer needs.

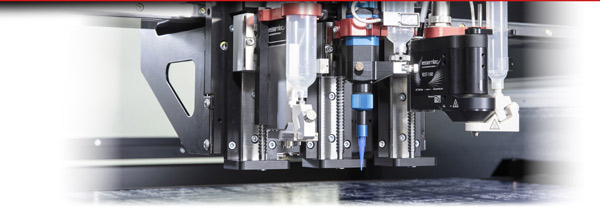

HIGH-SPEED DISPENSING

Unique solutions for jetting and dispensing adhesive, solder paste, silver epoxy and other media for SMD and related market segments. Several dispensing heads can be used in parallel to increase flexibility. Process adjustments are supported by automated quality tools and a user-friendly software-interface. High-tech dispensing, integrated into any high-speed line.

PRINTED ELECTRONICS

Printed electronics is the fastest growing technology in electronics manufacturing. Dispensing and component placement are done on flexible substrates, as foils, reel-to-reel, or various shapes and materials. The all-in-one solution offers different dispensing heads, an integrated vacuum table, as well as pick and place. This is an innovative and proven solution.

COMPLEX VOLUME REPAIR

Repair technology improves the cost and quality of the PCB overhaul process. Highly flexible solder paste jetting into pockets and flying over placed components with special tips and nozzles make this solution unique. The repair process is performed automatically on one single machine. The throughput can be increased with several components repaired in one run.

BEYOND SMT

Standard machines with dispensing & pick and place are adapted to customer needs to offer a quick response to todays or future market demands. Together with our customer, we develop new applications for medical, aerospace and automotive markets and offer proven solutions for sensors, batteries, LEDs, smart-homes, smart-devices, etc.

![[Translate to Englisch:] Essemtec Productronica München 2023](/fileadmin/_processed_/d/4/csm_Essemtec-Productronica-2023_6f21035e10.jpg)