One of the largest growth sectors in electronic engineering is LED technology. The latest market forecasts predict a turnover of more than 33 Billion US Dollars in this segment for 2019. In 2017 LED technology accounted for 22% of artificial light; in 2022 it is anticipated to be 63%.

One could think this is big business for everybody in this market sector. But this is only partially true because the price for a LED lamp is now less than half of what it was two years ago. European SMEs especially are quite badly affected and had to develop survival strategies.

MAL Effekt in Bebra, Germany, is one of the successful companies in this tough LED business. Since the very first days of LED technology they have produced highly sophisticated LED illumination solutions with just 75 employees. The question is how does such a small company cope with the global competition?

Markus Vockenroth explains: “It makes no sense to compete in price against Asia or large corporations. As OEM and EMS we are specialised on complete, customer specific, solutions. We focus on a high production level and have four SMD lines from Essemtec, along with several high-tech machining centres for the mechanics. So, we can manufacture everything from the circuit to the heat sink, all under one roof. For example: LEDs that are not mass products can be difficult to mount; they can remain stuck on the tape, have unusual forms and light domes that are not allowed to touch – one needs to be very experienced. For instance, we manufacture special vacuums for the SMD machines in-house ourselves. We are always thinking about how we can become better and/or faster, and how we can stand out from our competitors, that’s why our customers agree to pay for added value. For us, as a SME, there are five keys to success in this business:”

- High production levels, and therefore extremely fast reaction times

- Investment: In the last two years we invested, for example, in two additional placement lines and increased our performance by more than 60%

- Deep and close customer relations; to serve local customers exclusively and to understand the customer’s needs

- Generating of customer specific solutions in the highest quality with the best delivery time from concept to final product

- To offer specialty products that other companies cannot produce

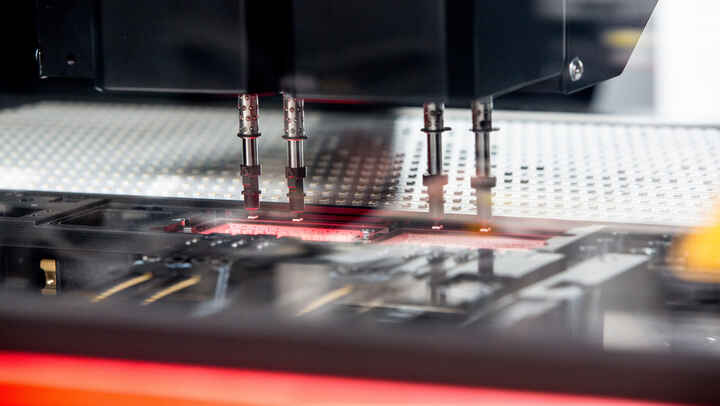

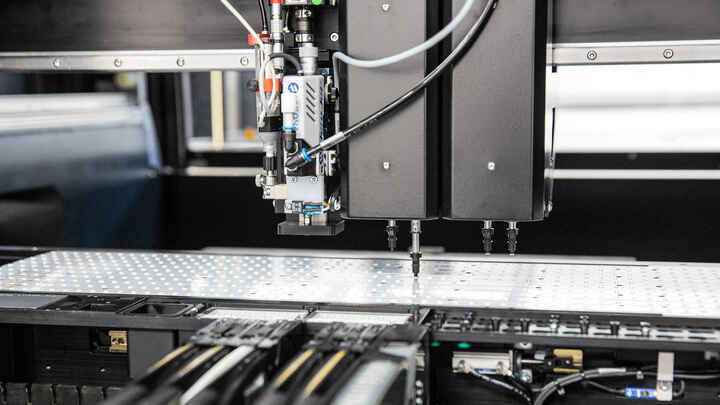

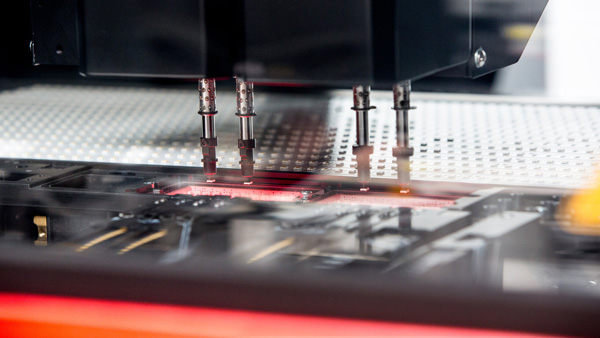

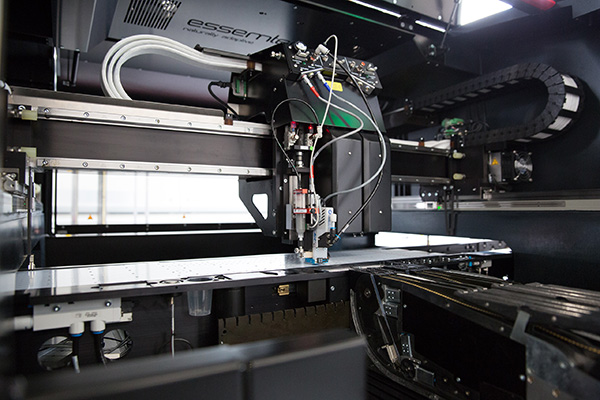

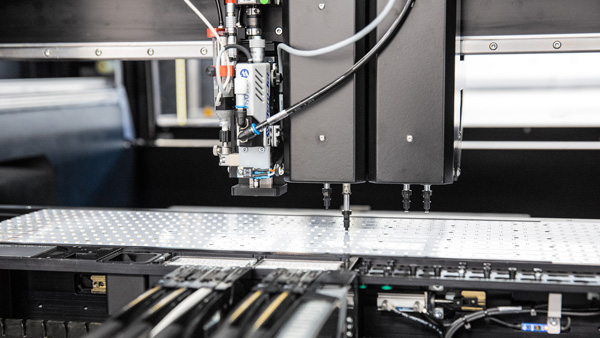

LED long boards of up to 1.8 m are one of these specialty products; this is a niche option only a few providers can offer. Together with Essemtec, MAL Effekt developed a state-of-the-art long board production solution for PCBs up to 1,800 mm x 610 mm.

They also developed a new transport system to meet the high-quality requirements. Most systems clamp only in the mounting area and that’s why the PCB overhang could swing or the oversized PCB could get entangled while indexing. This can lead to mounted, but as yet un-soldered components, snapping away from the PCB.

The new system from Essemtec always clamps the full length of long PCBs and so guarantees high process security. Historically the stencil print of long boards has been a problem; good quality long board stencil printers are hard to find and extremely expensive. Essemtec solved this problem by using a solder paste jet valve within the pick and place machine. The whole process is conducted in the SMD mounter, which means one also save the stencil printing production step. The first long board LED products manufactured on the new Essemtec pick and place line are already in production.

Essemtec will present the Puma Long Board Version at the upcoming SMT exhibition in Nuremberg. Visit us at booth 4-318.

_____________________________________

About M.A.L. Effekt Technik GmbH

M.A.L.`s core business is the development, production and marketing of innovative, bespoke LED modules. Together with our highly qualified staff and high-quality machinery, we develop a custom solution for every one of your requirements. From the first sketch to the first prototype, samples and, finally, production, we do everything ourselves! https://www.mal-effekt.de/

![]()