NASA’s “Journey to Mars” is striving to have astronauts land on this fascinating planet by the end of the decade. Essemtec is excited to be part of this historic mission!

The exciting quest to land astronauts on Mars is coming closer and closer to reality, and NASA’s (National Aeronautics and Space Administration) goal is to successfully execute the mission by 2030. This project is extraordinarily complex, consisting of many phases, and is only possible with the assistance of numerous partners – and Essemtec is extremely proud to be one.

Since 2006, Essemtec (a division of Nano Dimension) has supported NASA’s Marshall Space Flight Center (MSFC) – entity charged with mission-critical design, development and integration of the launch and space systems required for space operations, exploration, and scientific missions – by supplying easy-to-use, high-quality production equipment for electronic assembly that is playing a key role in the development of state-of-the-art electronics.

Picture 2 NASA’s George C. Marshall Space Flight Centre has been around for close to 60 years and is responsible for providing mission-critical design, development and integration of the launch and space systems for space operations, exploration and scientific missions.

MSFC’s Electrical Fabrication & Assembly Facility provides printed-circuit assembly and cable fabrication all the way through chassis assembly and integration. The electrical shop provides the capability for both through-hole and surface-mount component assembly on printed circuit boards (PCB). MSFC originally purchased an Essemtec solder-paste printer and its FLX automated pick-and-place machine. Most recently, MSFC upgraded to Essemtec’s innovative FOX 1 pick-and place system that incorporates enhanced technology to aid in the building of engineering test boards and prototypes for the space station.

Essemtec is committed to fulfilling its own quest to provide MSFC – and all its customers – with reliable, productive equipment and top-notch support. Initial Essemtec systems have been in operation at MSFC for 15-plus years, and they continue to meet the challenge of flexibility. MSFC engineers work with diverse types of electronic/circuit boards, so Essemtec’s Fox 1 with its large feeder capacity provides a significant benefit (as is its compactness that frees up critical lab floor space).

Picture 3 Essemtec’s FOX 1 on the floor of MSFC’s lab. NASA uses the FOX to help build engineering test boards, prototype and build boards for the space station.

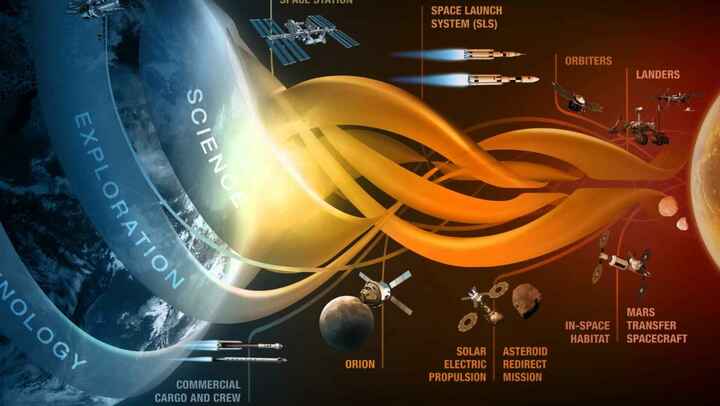

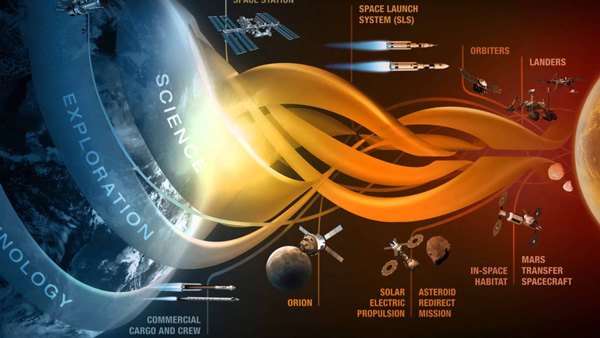

Later this decade, powered by the most powerful rocket ever built, a cadre of astronauts will blast off into space aboard Orion (complete with its state-of-the-art electronics) and travel nearly 35 million miles (56 million kilometers) over seven months and, at the end of their journey, land on Mars. They will call this fascinating planet “home” for two years to conduct their research and, 1,000 days later, will touchdown back on earth.

This Journey to Mars will depend on MSFC’s ability to develop, demonstrate, and apply innovative technologies and capabilities for NASA. Collaborations with key suppliers like Essemtec are critical to MSFC’s mission of honing existing technologies and inventing new ones.

_________________________

For more information, contact Adam Gowan, Lead, Electronic Fabrication & Test Team at NASA’s George C. Marshall Space Flight Center in Huntsville, AL 35812 or visit www.nasa.gov/marshall.