Since the commercial introduction of LED technology more than one decade ago these shining little diodes are so omnipresent that no one could now imagine life without them. One example out of the many are the LED back lights or the intelligent headlights of vehicles; although this actually concerns all kinds of illumination. A very special use of this LED technology is created by Peter Platz Spezialglas GmbH from Wiehl-Bomig in Germany. LED in glass panels bring intelligent animation to life and generate emotions on facades, tables, floors and glass walls. This very specialised production is conducted on converted Essemtec assemblers.

Picture 1: Bridge of peace in Tbilisi Georgia with powerglass® Source: I. and V. Goliadze

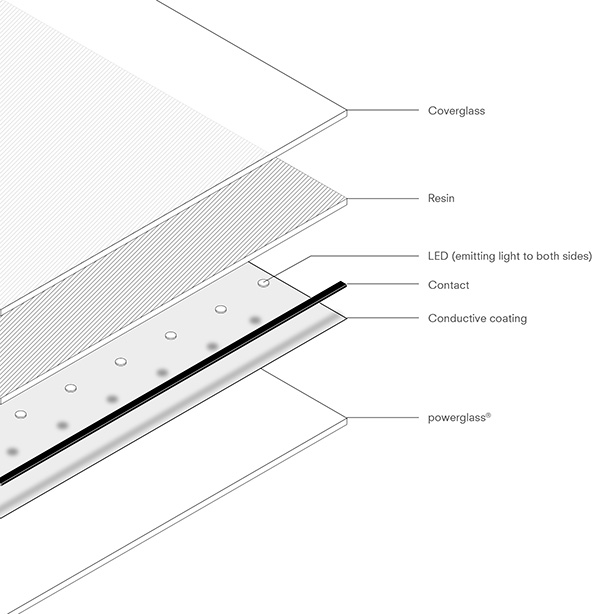

LED inside the resin laminated glass is supplied with electrical power via invisible circuits on the inner glass surface; just about any LED layout is possible. Two contact bars, usually located along the long glass edges, are used to feed power into the conductive glass surface and an external power supply is always included.

Picture 2: Facade with powerglass® Source: Peter Platz Spezialglas GmbH

Further development of LED lighting technology has made it possible to merge glass and light without wires into powerglass® and generate fascinating light effects. Light emitting diodes embedded in cast resin composites offer a variety of advantages:

- Can be positioned nearly anywhere

- Wireless power supply

- Lights from both sides

- Low power consumption

- Marginal heat development

- Protected within the resin composite

Peter Platz Spezialglas produces powerglass® according customers’ own specifications. From cutting the glass to the final inspection – the entire production takes place in their own plant. The completed powerglass® panels come with pre-wired connecting cables (protected against ESD damage) and power supplies.

Video of an intelligent façade in glass

<iframe frameborder="0" height="315" src="https://www.youtube.com/embed/WTPaJjbFEaA" width="560"></iframe>

Peter Platz could not find a standard solution to assemble the 3m long and 1.2m wide glass panels. So they decided to buy a Essemtec SMT assembler with a dispenser head and to convert it in such a way that the machine was able to accept the glass panel width. Thanks to the assembler’s flexibility it was possible to manage this special application. The main difficulties were with the recognition of the structures in the glass for the reference badge detection, the clean dispensing on glass and the very high accuracy while placing the LED component.

Picture 3: Layer of a glass panel Source: Peter Platz Spezialglas GmbH

_____

About Peter Platz Spezialglas GmbH

Peter Platz Spezialglas GmbH specializes in processing technical glass. Founded in 2014, this young enterprise looks back on a family tradition in the field of glass processing that goes back decades. At their site in Wiehl-Boming near Cologne a team of engineers, technicians and craftspeople develop functional glazing that complies with highest quality standards. With the powerglass® range, the company offers individual laminated LED glass solutions for sophisticated projects around the globe. The areas of application both indoors and outdoors are numerous; as a design element or to set stunning visual marks by creating media facades. (http://www.glas-platz.de/)