Why BGA re-balling is needed?

There are several reasons for BGA reballing, including economic, technological, reliability, sustainability, and specific industry requirements.

Economic Reasons:

BGA components can be expensive. Salvaging and reusing these components through reballing saves significant costs that would otherwise be spent on replacing them. This practice supports the circular economy by reducing waste and the need for disposal of unused components.

Sustainability and Reduction of Waste:

Reballing BGAs contributes to sustainability by extending the lifecycle of electronic components. By reusing components, the demand for new materials is reduced, which in turn lowers the environmental impact associated with manufacturing and disposing of electronic parts. This practice helps in minimizing electronic waste, promoting a more sustainable approach to electronics production and consumption.

Technological and Reliability Reasons:

Technological failures often involve the separation or cracking of BGA balls, leading to poor electrical connections between the BGA and the PCB substrate. These issues are mainly caused by mismatched Coefficients of Thermal Expansion (CTE) between the BGA and the PCB, as well as mechanical, material fatigue, and thermal stresses on the assembled board. The balls at the edges of the BGA package are particularly susceptible to cracks.

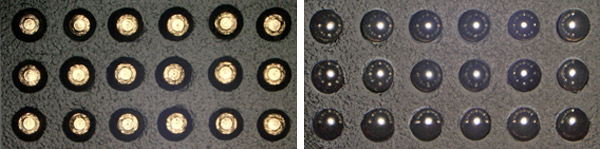

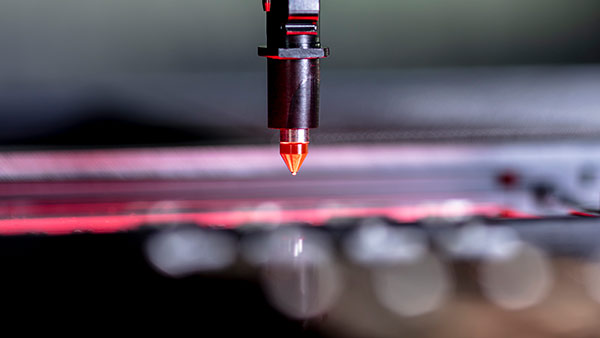

Picture: Dispensed Flux and solder balls

Other Reasons for Reballing:

Defense and Aerospace Segments:

In industries like defense and aerospace, designs that use Pb-based soldering are often required to continue using the same technology and materials. If BGAs are manufactured with ROHS-compliant materials, they must be converted to Pb-based ball materials. Conversely, there may also be a need to convert from Pb to ROHS-compliant ball materials.

R&D Centers:

Research and Development centers that create numerous Proof of Concept (POC) designs often want to reuse expensive BGA components. Reballing provides a straightforward and cost-effective way to enable this reuse.

Picture: Microscope view on placed solder balls

Main techniques for BGA re-balling

There are several techniques for BGA reballing used in the industry. The three most common ones are:

- Stencil Placement, a very manual operation prone to error

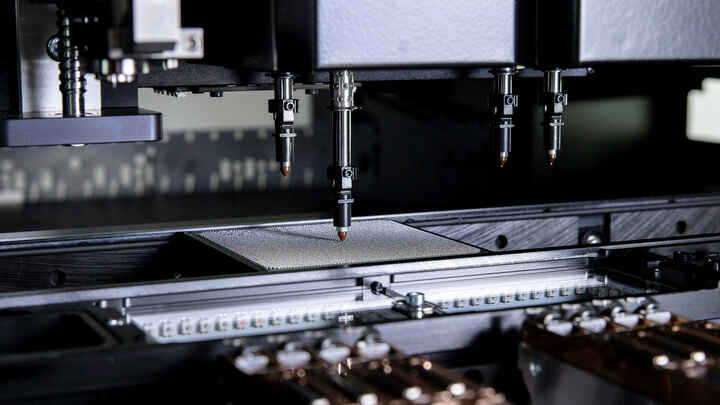

- Robotic Ball Placement with Laser Soldering: In this technique, a robot places the balls and then uses laser soldering to secure each ball individually. This technic is offering accuracy but requires a long pre-processing and soldering phase.

- Robotic Ball Placement with Reflow: This technique involves robotic dispensing of flux selectively, followed by robotic placement of balls, and finally, a reflow process to solder the balls to the package. Essemtec is now offering this solution on the FOX and PUMA equipment.

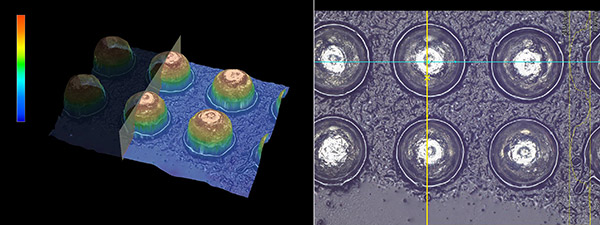

Picture: 0.5 mm solder ball measured by vision system

Essemtec Solution:

Once the solder ball have been removed and the BGA has been cleaned and prepared the Essemtec process could take place.

Dispensing of flux paste:

The precise dispensing of the soldering flux in the accurate quantity is basis for a successful process.

Applying new solder balls:

Solder balls of the correct size and composition are applied in one run with the flux dispensing to the BGA component using the specialized Essemtec equipment. The accurate ball placement is critical for proper connections and functionality.

Essemtec Solution could place ball from 0.25 mm up to 1 mm and could work with traditional ROHS complaint material but as well leaded solder ball for specific application.

Once the BGA has been reballed, the next step of reflow process could be setup in an appropriate oven. This melts the solder and creates a strong connection between the component and the PCB.

_____________________________________

Summary and Conclusion:

The all-in-one process capabilities, featuring integrated flux dispensing and accurate ball placement, enable a smooth, reliable, and fast BGA reballing process. With proven results and successful reliability tests, this process supports a variety of ball materials and dimensions. By avoiding the accumulation of expensive scrap and promoting a circular economy, the all-in-one robotic BGA reballing process proves to be a cost-effective method for reusing expensive BGA components. Additionally, it allows for the replacement of ball materials to meet specific design requirements.

Watch the process video on BGA dispensing and reballing