As a Swiss medium-sized company, Essemtec must always justify the possible higher investment costs with solutions that provide the customer with clear added value. Therefore, it is necessary to cover customer specific solutions with the standard modules. Essemtec's standard solutions are modular and thus, we are able to respond and adapt swiftly to customers’ needs. We also check with our customers in advance if an investment into a non-standard solution is reasonable for both parties in terms of risk and cost. Here are some examples.

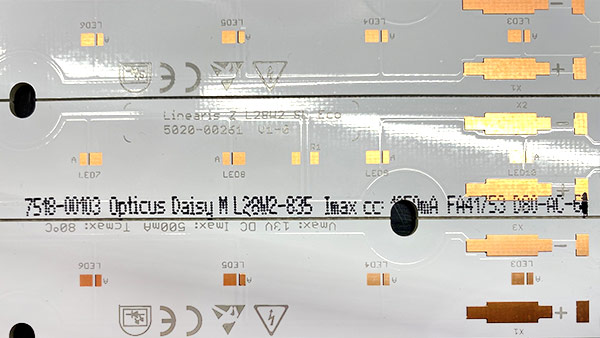

MAL Effect and automated ink jet labeling of printed circuit boards

MAL Effekt’s core business is the development, production, and distribution of innovative, customized LED modules. To succeed in the highly competitive LED market, the MAL Effekt team is always considering how it can be better and faster to clearly differentiate itself from the competition. In doing so, the company relies on a high level of production integration.

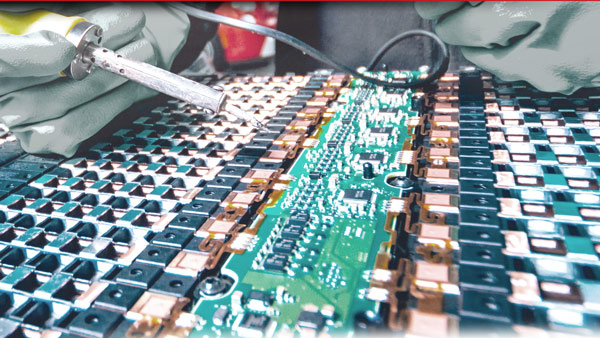

Four SMD lines from Essemtec and several high-tech central processing units for the mechanics are available in the production. So, everything - from the circuits to the cooling elements - is manufactured under one roof.

The challenge

In such a production, many labels are glued onto printed circuit boards. Several employees at MAL were needed to stick the correct labels onto the printed circuit boards. This was costing the company more than 100,000 euros per year.

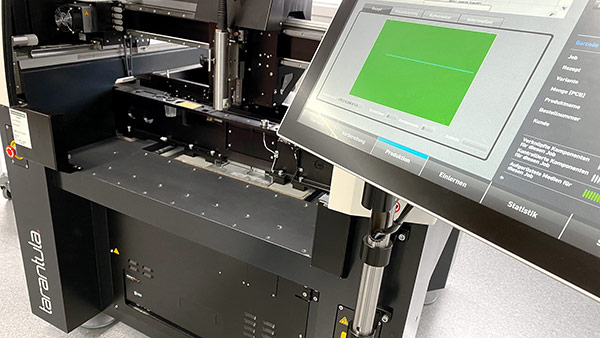

Markus Vockenroth, CEO of MAL Effekt, wanted to improve this process and asked Essemtec to integrate an ink jet valve into the Essemtec dispenser module.

The requirements were:

- Automated inline system from magazine to magazine

- Ink jetting of clear text with xx mm, 1D and 2D code

- Adapted flexible standard system

- ROI well below two years

The solution

Essemtec has accepted the challenge and together with MAL Effekt has integrated these requirements into a Tarantula dispenser. The solution was installed and has been running for several months without any problems.

ETO Sensoric GmbH production of sensors with P&P, dispensing, and mounting caps

With passion for innovation, ETO develops and produces electromagnetic drive components, sensors, electronics, and software for the regulation and control of highly dynamic processes in the fields of mobility, automotive engineering, industrial plants, equipment for medical technology and food processing. 2,500 employees worldwide work to ensure the success of ETO's customers.

The challenge

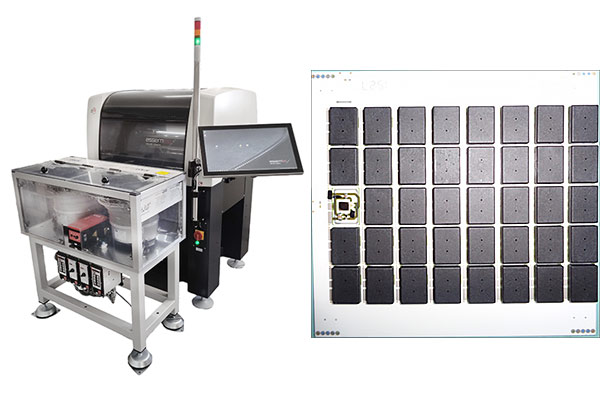

- High performance manufacturing line for sensors

- Dispensing and placement of protective caps in bulk over the sensor module on hybrids in the clean room

The solution

Essemtec solved the challenge by integrating high-performance bulk feeders into standard machines. The corresponding processes were implemented and optimized. Further options were developed to integrate the systems into the ETO environment.

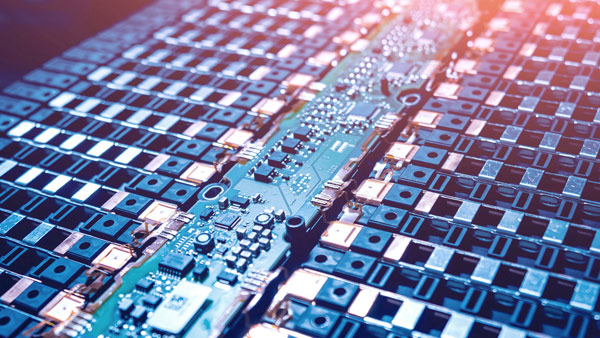

ITEN, solid state rechargeable SMD micro batteries

ITEN's products are the ideal energy storage solution for electronic device that requires a backup power in case of power failure. They provide high peak currents (e.g. in case of RF transmission), or they can be used as a main energy source to power a network of wireless autonomous sensors, implantable or medical devices, wrist watches, smart cards and identification tokens, smart shelf labels, etc.

The challenge

- Batteries must be populated with high precision and must not float.

- Highly accurate dispensing processes must be used for this purpose.

- Placement of lead frames for batteries of batteries that are randomly loaded.

- Measure the batteries, which have large tolerances and correctly place pin 1 anode/cathode

- Define predefined feeding means

The solution

- Standard pick and place processes with the appropriate dispensing system are used. These are all-in-one solutions from Essemtec.

- Further development of the vision software to recognize the battery and to rotate and place anode (cathode) correctly

- Process optimization to meet this application

![[Translate to Englisch:] Mikro-Batterien Produktion](/fileadmin/_processed_/8/0/csm_Essemtec-Specialities-Micro-batteries_99dbaadd93.jpg)