Mostec AG is a Swiss SME located in Liestal, specializing in the development, production, and testing of custom electronic systems, primarily for the pharmaceutical and chemical industries. Due to the wide variety of products, the relatively small batch sizes with multiple changeovers per day, and the emphasis on quality and punctuality, Mostec also relies on its own complete SMT production line.

In 2023, it was decided to expand the assembly line with an additional module. Since the stencil printer also needed to be replaced due to age, the question arose whether the process flow should be changed—specifically, whether to forgo stencil printing and instead implement 100% solder paste Jet Printing. The following report discusses the challenges and results of this process.

1. Initial Situation

a. Personnel

Mostec manages the entire SMT production with just one operator. Therefore, the considerations also included simplifying processes as much as possible. The line needs to run as autonomously as possible despite frequent product changes, which was not possible in the current state.

b. Quality

New products featuring super fine pitch connectors and other components with very small pad sizes were introduced into production. The printer struggled to consistently process these components cleanly and at a high level, resulting in errors and costly rework or additional inspections.

c. Environmental Protection and Ease of Use

Mostec places great importance on handling resources as efficiently as possible. It was repeatedly noted that up to 35% of the solder paste was wasted with the stencil printer. Applying the solder paste and other processes, such as cleaning the stencil, were only possible with the use of chemicals.

d. Processes

Certain required processes, such as applying solder paste in cavities, printing in steps, varying solder paste quantities per pad, printing super fine pitch components, and rapidly creating prototypes, were difficult or even impossible to achieve.

2. Evaluation

Mostec considered the possibility of eliminating a stencil printer and using the newly acquired pick-and-place machine to jet solder paste across the entire production and product range. The advantages were quickly recognized, but Mostec had concerns:

- The process speed of jetting is slower than a stencil printing cycle. Would this cause delays in assembly?

- Can jetting meet the high quality standards, particularly concerning super fine pitch?

- Can programs be created quickly enough to prevent downtime?

- Can the objectives outlined in 1.a – 1.b really be achieved with a jetting process?

- Will production costs be lower with a jetting process compared to a stencil printer in the Mostec environment?

3. Experience with the Solder Jet Printing Solution

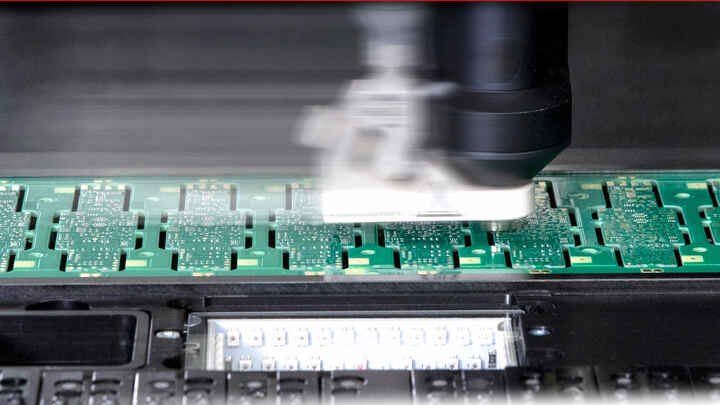

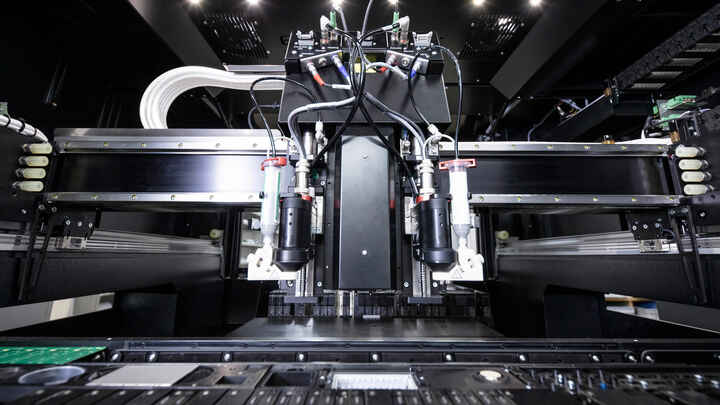

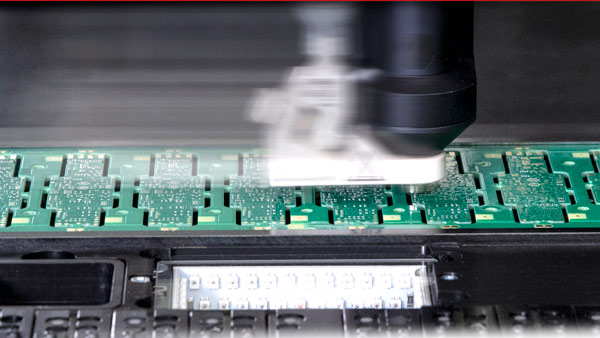

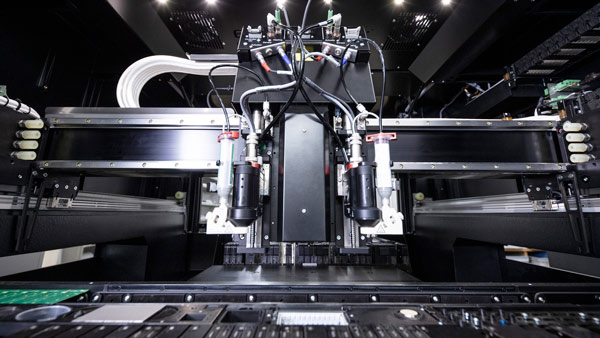

The line at Mostec now consists of a magazine loading station, an initial SMD pick-and-place machine with two integrated solder jet valves for small and large dots (all-in-one), followed by a second pick-and-place machine, and a subsequent magazine unloading station.

The line has been in production since February 2024. According to Fabian Häfelfinger, Project Manager at Mostec: "The experiences have been consistently positive" (see the video below). The solution has exceeded our high expectations.

- Mostec has significantly fewer errors in the solder paste process on the board.

- Operating the machine now only involves changing cartridges every few months and performing a weekly cleaning that takes about 10 minutes.

- Work on the line has been drastically reduced. There is no longer any waste of solder paste.

- The performance is sufficient to always dispense faster than assembly.

Mostec can highly recommend the solder paste jetting process for high-flex, low-volume SMD assembly lines.

Further details:

Process Step / Previous Issue vs. Potential of a Solder Paste Jet Printing System

Process Step / Previous Issue | Potential of a Solder Paste Jet Printing System |

1. Placement of Solder Paste Preforms | Replacing preforms: Cost savings on preforms, reduction of feeder positions, reduction of line cycle time, and minimizing post-soldering work due to errors with preforms. |

2. Step Stencils for Prototypes | Eliminating the need for step stencils for prototypes and products with small batch sizes. |

3. Steps (Islands) - Step Up | Eliminating the need for steps for individual, critical components. |

4. Steps Technologically Not Feasible (Spacing Rules, Size) - Step Down | Optimizing solder paste volume for critical components. |

5. Dispensing in Cavities - Depth Printing | Automating the process step, saving a process step, and addressing a technological challenge that is currently unsolvable (even manually). |

6. Prototyping is Time-Consuming | Rapid implementation of prototypes since no stencil is required. |

7. Layout Changes, Changes to a Component, or Changes to the Existing Stencil | Often, a new stencil is not required; dispensing on landing areas for preforms can be directly modified. |

8. Poor Solder Joints After Reflow Process | Automated post-dispensing; adjusting solder paste volume reduces rework on components (mitigates serial defects). |

9. Poor Paste Release from Stencil -> Defect Detected by 3D SPI | Post-dispensing of paste before the placement process. |

10. Two Different Systems | One unified system with a single process database. The solder jet patterns are linked to the SMT component or can be directly imported via Gerber files. |

11. Incorrect Stencil (Order Error, Manufacturing Error) | Production stoppages can potentially be avoided, allowing for a spontaneous response to manufacturing issues. |

Customer Testimonial - Solder Paste Jetting

____________________________

About Mostec AG:

For over 40 years, MOSTEC AG has been engaged in the development of electronics for measurement and control systems. Electronics development is our specialty and our passion, which is why we at MOSTEC guarantee customized solutions, fast service, and the highest quality of our products.