‘’We are really happy with the machine and the support that we have had from Altus and Essemtec throughout.” Rob Horsley, Nexperia Senior Surface Mount Engineer.

Background

Nexperia, a global leader in the semiconductor industry, has established a strong reputation for innovation and quality. With over 14,000 employees across Europe, Asia, and the United States, Nexperia is known for its high-volume production and development of essential semiconductors that power a wide range of electronic designs, from automotive to consumer applications. One of the company’s manufacturing facilities in Stockport, renowned for its dedicated TrenchMOS wafer fabrication and over 50 years of semiconductor legacy, required a significant upgrade to its Surface-Mount Technology (SMT) production capabilities.

The Challenge

In 2023, Nexperia was looking to enhance their SMT production capabilities and invested in equipment from Essemtec, leaders in adaptive SMT pick-and-place equipment for both high-speed- and micro-dispensing, to optimise the production operational flow. While capable of placing 01005 components, their existing unit needed to support larger components, such as 72mm connectors, to meet the demands of increasingly complex electronic designs. Additionally, they required a machine with an 'all-in-one' concept that could dispense both epoxy and solder paste as needed, providing flexibility and future-proofing their production processes.

The Solution

Nexperia conducted a comprehensive market review to find a partner capable of providing advanced equipment and understanding their specific needs. This process led them to Altus Group, a leading distributor of capital equipment in the UK and Ireland.

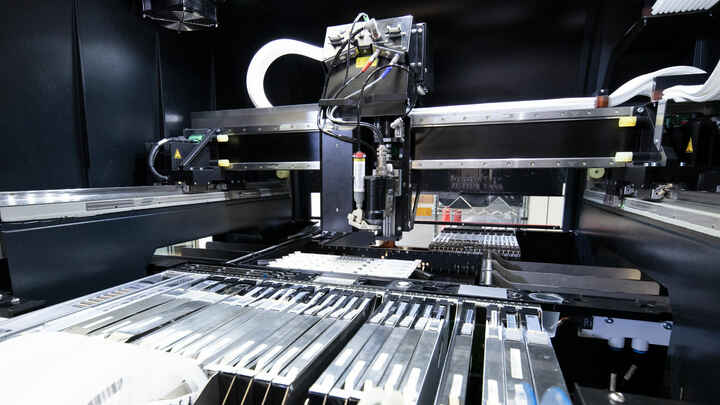

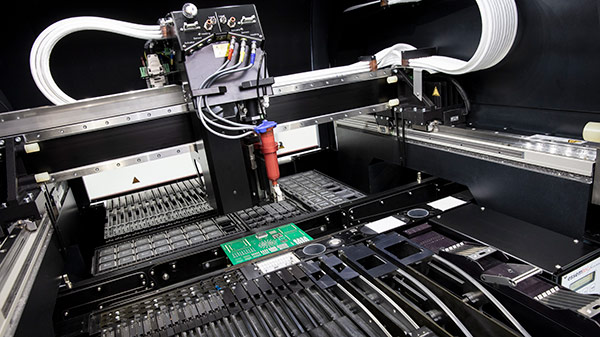

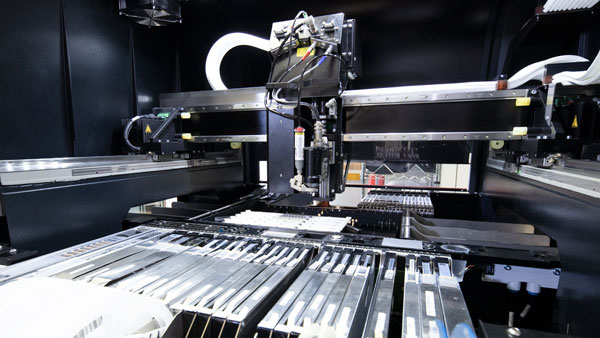

After careful consideration, the Essemtec Fox Multifunction Cell (ALL-IN-ONE) Pick and Place system was selected as the most suitable solution for Nexperia's requirements. This advanced system offered a combination of features aligned with Nexperia's vision for their upgraded SMT production line.

Key Features of the Essemtec Fox ALL-IN-ONE

The Essemtec Fox ALL-IN-ONE includes several advanced features, making it the ideal choice for Nexperia. The machine is capable of placing a wide range of components, offering complete flexibility.

Its integrated concept allows for dispensing epoxy and solder paste, providing Nexperia with unmatched versatility and ensuring its production requirements are met. “We were really drawn to the all-in-one concept, which is unique and allows us to future-proof our needs,” said Rob Horsley, Nexperia Senior Surface Mount Engineer.

The Essemtec Fox ALL-IN-ONE offers several advanced features, including:

- Compact Footprint: The small size is perfect for space-constrained environments, allowing for efficient use of production space.

- Modular Design: Expandable in any direction and supporting up to 180 feeder lanes (or 120 inline), it is ideal for high-mix production requirements.

- Precision and Quality: Integrated 2D defect detection ensures precise, high-quality production runs.

- High Productivity: Quick changeover capabilities enable non-stop production, achieving a productivity of up to 12,000 components per hour (cph) on the Fox2 variant per module

Outcome

Implementing the Essemtec Fox ALL-IN-ONE has dramatically enhanced Nexperia’s SMT production capabilities. The machine’s ability to place and dispense in a single pass-through has optimised their production efficiency and flexibility. The compact footprint and modular design have allowed Nexperia to maximize their production space, while the integrated defect detection system has ensured the highest standards of precision and quality. “The machine is very flexible and versatile and is packed with features and capability when you compare it to other solutions in the market,” said Rob.

Charles Lower, Altus Sales Manager, added: “It has been great to see how the project with Nexperia has worked out and to get another satisfied Essemtec user in the UK and Ireland.”

Feedback

Altus’ comprehensive pre-sales process and exceptional aftersales support were instrumental in successfully implementing the Essemtec Fox ALL-IN-ONE at Nexperia. "The team at Nexperia had a refreshing approach to the machine selection, and it has been a pleasure to support them through implementation and show what we can do,” added Charles.

This meticulous approach guaranteed that the Essemtec Fox ALL-IN-ONE met all their expectations and requirements. Nexperia’s satisfaction with the support received during implementation and ongoing operations highlights the strength of their partnership. Rob concluded: "We are really happy with the machine and the support we have had from Altus and Essemtec throughout."

Integrating the Essemtec Fox ALL-IN-ONE system at Nexperia's Stockport facility marks a significant step forward in their SMT production capabilities. This investment, facilitated by Altus Group, has provided Nexperia with a versatile solution that addresses their current needs while preparing them for future challenges.

_________________________________

About Nexperia: