Endress+Hauser is a leading global supplier of measuring instruments, services and solutions for industrial process technology and automation. Endress+Hauser offers solutions for flow, level, pressure, analysis, temperature, data acquisition, and digital communication across all industries and guarantees reliable, safe, economical, and environmentally friendly processes.

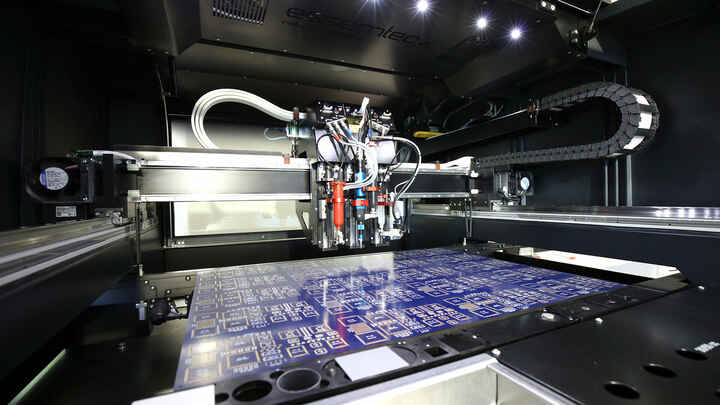

Essemtec is a Swiss machine manufacturer in the field of Surface Mount Technology (SMT). Essemtec dispensing solutions are used in 3 out of 4 production plants.

The benefits and added value of these systems in modern SMT production lines are highlighted in this short article, using Endress+Hauser as an example. Four years ago, the measuring instrument manufacturer carried out a worldwide benchmark analysis for dispensing systems. Essemtec won with its Tarantula and Spider dispensing concept.

Challenge

- Production with increasingly smaller batch sizes (up to 1) and higher output at the same time

- Smaller components, which must be glued and for LED application highest process accuracy is required.

- Different simultaneous processes: gluing, solder paste depot, conductive glue, UV glue

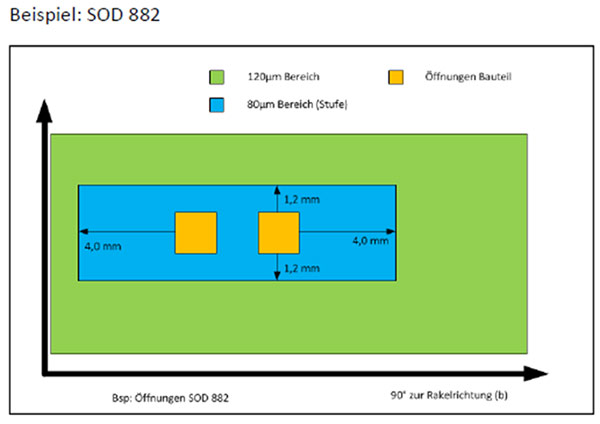

- Step stencils become too complex, up to 4 steps on one stencil. As there is not enough space between small and large components, no step can be inserted in the stencil in a process-safe manner.

- Process-safe production of foils, no screen printing possible (printed electronics)

- In future, solder paste or conductive glue to be applied in cavities

- Stable system that masters new products immediately without running in issues

- Changeover time close to zero

- Additional areas to be solved:

- Repair processes: desolder component, new solder paste jetting and placement

- Get rid of solder preforms and solder jet them

- Produce pin in paste quickly and efficiently

- Defective stencil, correction by jetting

- Deformed PCBs to be processed

Main criteria to solve the problem areas

From 1. the following main criteria resulted, which have to be fulfilled and solved:

- 3 dispensing processes in parallel on the system: jetting adhesive, jetting solder paste, dispensing conductive adhesive or alternatively UV adhesive.

- Process accuracy below 50 µm and better 50 dpm

- Target: all stencils have a thickness of 80 µm and all higher levels up to 280 µm are jetted using solder paste

- Process speed higher then general line speed

- Fully automated program generations

- Horizontal integration of Endress+Hauser's software tools. ERP, MES, Siplace pro, Mentor. Download and program loading fully automatic.

- Can be integrated vertically into OIC, Siplace Pro and thus batch size 1 without operator intervention.

- Industry 4.0 capable. Operation only for cartridges. changeover time to zero

- Solutions for all points listed under 1

Examples

Some of the challenges and solutions listed above will be discussed in more detail. Thus, the added value of the dispensing process in the modern SMT production line will be considered.

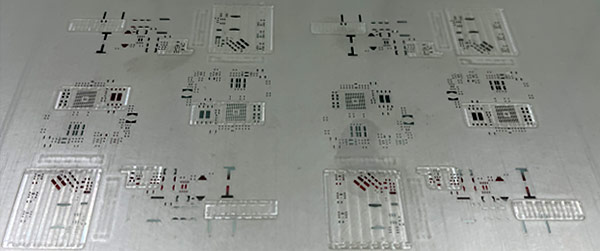

- Step stencils

In today’s high-tech products, it is no longer possible to manufacture with only one stencil thickness. Smallest components 0201 and large SMD components require different solder paste depot. Complex and elaborated step stencils are used for these purposes.

Picture: Step stencil

A defined distance must be maintained between the small volumes and the large ones in the squeegee direction in order to run this process in a proper way (distance rule)

If this rule can no longer be observed due to excessive packing density, only the jetting process can help. The steps are applied with a flexible solder paste jetter. The solution to the problem can thus simplify the process or create the solution in the first place. This way one can eliminate the use of complex and expensive stencils. With new products, this problem of increased solder depots is often only seen in the production of 0 series. With a jetter solution, it is possible to react immediately on this issue.

Further goals and potential solutions of a future dispenser should be in the following:

| Process step / Problems | Potential of a Dispenser |

1 | Loading solder paste preforms | Replacing the preforms: cost saving for preforms, (reduce feeder places) / reduce cycle time of the line / re-soldering due to errors with preforms |

2 | Stop using step stencil for the NPI process or small lot sizes | No step stencils for e-patterns and for products with small batch sizes |

3 | Steps (islands) - step "up" | Elimination of steps for single, critical structural components |

4 | No possibility of technology process in various stages for steps (control of space and size) – downwards | Optimum solder paste volume for critical component |

5 | Dispense in cavities | Automation of process steps / reduction of one process step / technologically not feasible with current processes (no manual process possible) |

6 | PIP (Pin In Paste) witch need to be processed on the solder wave – technology wise it can not be printed under 45° squeegee | Savings of one process / tooling costs |

7 | Change of layout, change of a component shape, or change of the existing solder stencil | A new design screen is not always required / Dispensing of landing pads for pre-forms |

8 | Defective solder joints after the reflow process | Auto re-dispensing / adjust solder paste volume directly after printing process / less rework of components (serial defects) |

9 | Not proper solder paste release from stencil -> 3D SPI fault pattern | Re-dispensing of solder paste before the component assembly process |

10 | Incorrect design stencil (order error, manufacturing error) | Production stop can possibly be prevented / Spontaneous reaction to production problems with solder jetting. |

Result

After evaluating all possibilities, the company decided to invest in Essemtec's Tarantula dispensing solution. Today 7 systems are in use in the three Endress+Hauser factories.

Tarantula with 3 dispensing processes: SMT adhesive jetter, volume dispenser, solder paste jetter

Florian Grether, Manager Production Engineering Endress+Hauser Level+Pressure announces:

"In the evaluation phase, Essemtec demonstrated in application tests that all our requirements in terms of jetting and dispensing can be carried out in an excellent process quality. This also under the dot dispensing speed required by us. The requirements, especially in terms of software, were met and implemented. Particularly noteworthy is the programming with OPM and ASCII files for gluing programmes and Gerber for solder paste dispensing, as well as the achievement of an automatic programme change with OIC and a practical change over time of zero.

Our 4 Tarantulas in Maulburg have been in operation for 3 years and are among the most reliable systems in our SMT lines. Our expectations have been fully met. Due to this success, 2 more manufacturing plants have invested in the Essemtec solution."