Every day approximately 140,000 tons of electronics are disposed. A large percentage of these are SMT circuit boards. Fake components are installed every day, causing millions of dollars of damage in production. If the economic and ecological footprints are considered, many users today come to the conclusion that the repair of PCBs or the replacement of critical components with new technologies is worthwhile in order to extend the life of the product.

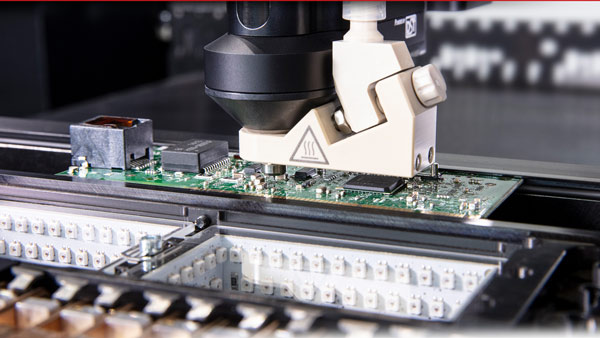

Essemtec has generated a solution to repair complex PCBs with high performance concept.

In the circular economy, one tries to prevent or reduce waste throughout the life cycle of a product and to extend the life of the product or to improve an existing product with new components.

This should also apply to electronics production, and in particular to SMT component placement.

There are various reasons why parts are produced incorrectly even in the most modern placement lines:

- Fake components

Since the pandemic and the shortage of materials for SMT components and processors, fake components have increased dramatically. The faults are found very late in the process. In most cases, 100s or 1000s of PCBs are already wrongly assembled because the AOI cannot detect them. - Process errors in production

Wrong components are mounted or components in the tray are fitted the wrong way in the machine. This leads to placement errors. - Technical process errors

Process errors occur in the SMT line, resulting in a faulty PCB.

Furthermore, processors are replaced by new versions to extend and improve the life of the product. Defective PCBs are also repaired in the field for a variety of reasons.

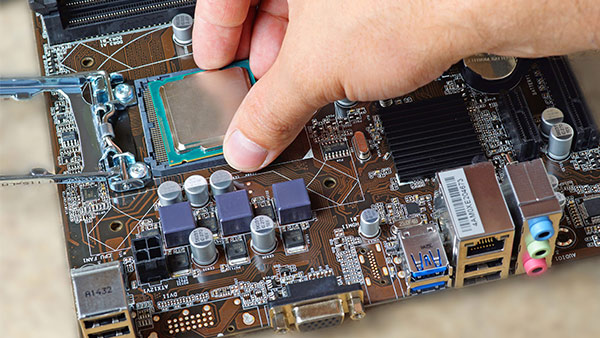

The manual repair work is time-consuming and sometimes difficult to carry out on high-pin components. Special stencils must be made, one component can only be inserted at a time, and experienced operators are needed. The entire process is expensive.

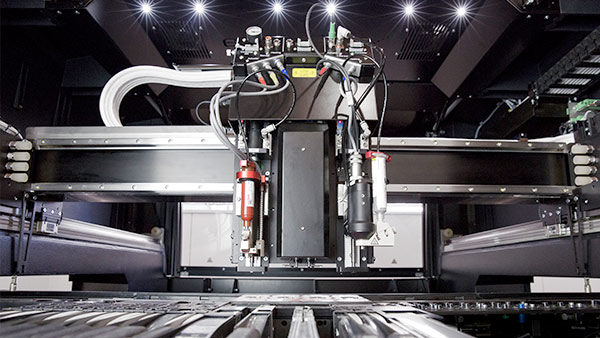

Essemtec has generated a solution for high-performance repair using the Puma and Fox All-in-One equipment, which jets solder paste and assembles the components s in a single machine. The post-jetting of solder paste onto the pads as well as the replacement of highly complex components and BGAs is fully automated. This is also achieved with tightly pre-assembled PCBs.

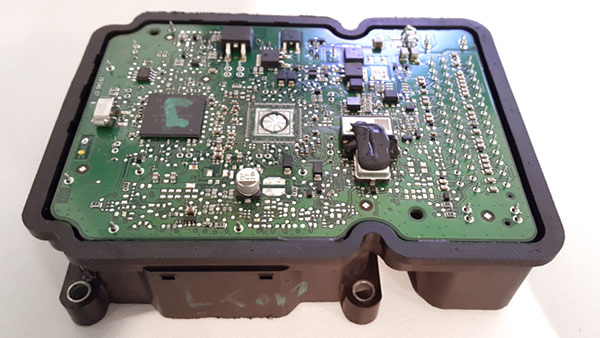

Case 1: Actronics - Repair of an ABS control unit

The ability to restore defective products contributes to a sustainable circular economy. In a world where demand for sustainable applications is increasing from consumers as well as from legislation and regulation. ACTRONICS offers a solution for the reuse of defective electronic modules in the automotive industry with overhaul.

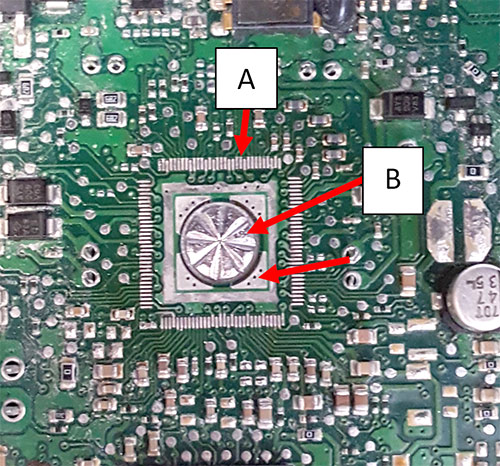

ABS control unit with desoldered main processor

Component TQFP with SNPB solder

Zone A: 400 µm pitch component, Zone B High amount of solder for cooling element

High-performance jetting from the solder with special nozzles to fly over the parts and without touching existing components. Collision protection.

400 µm pitch is jetted with a dot diameter of 265 µm +/-17% 3 sigma, the large volumes are shot with dot sizes 670 µm and very high power.

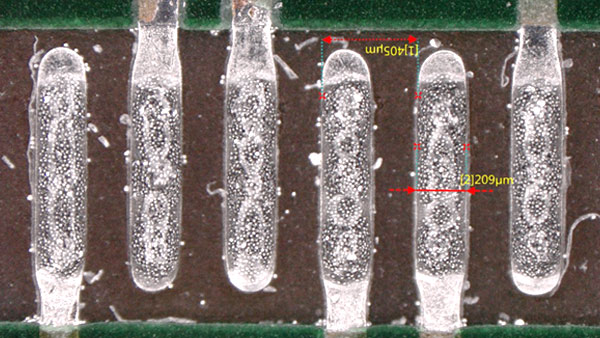

World wide number 3 computer company which has their products manufactured in China by one of the top 3 ODM manufacturers

Presently seven Essemtec machines are in operation at different production sites and another 15 will follow shortly. Repairing mainboards etc. Soldering of BGA's 1500 pins on tightly assembled circuit boards.

Special nozzles to ensure protection against collision with other assembled components

Dot diameter 294 µm, +/-6.2%, 3 sigma

Summary

Essemtec's concept has been proven and well established in the market.

- This repair method increases the process speed by at least 500% compared to manual or semi-automatic repair.

- Different components can be repaired or replaced inline and in the same setup.

- Repair of 400um pitch components on a densely populated PCB is possible.

- Different solder pastes can be used such as lead-free and leaded LTS.

- Lesser-skilled operators can run the process.

- The process can be easily optimized at any time.

- In most cases, an excellent ROI is achieved, and the costs are massively reduced compared to a manual process.

Authors: Irving Rodriguez, Jürg Schüpbach Essemtec AG

![[Translate to Französisch:] Komplexe SMD Reparatur](/fileadmin/_processed_/8/8/csm_Essemtec-Complex-SMT-PCB-Repair_a5cc6fd05c.jpg)

![[Translate to Französisch:] Puma Bestücker](/fileadmin/_processed_/3/b/csm_Essemtec-Complex-SMT-PCB-Repair-Puma_0477bf4380.jpg)